Technical Specifications / Technische Spezifikationen

GENERAL DESCRIPTION

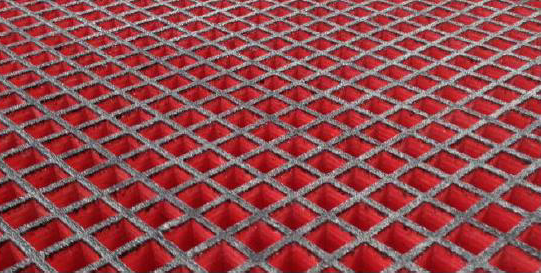

GRP Gratings are produced in special matrix molds. The grating consists of three main components: Resin Mix (2), Fiberglass (1), Pigments (mixing of pigment and resin). The percentage of resin and fiberglass - 70% to 30%. Fiberglass is located in TWO directions.

Figure 1 - FiberglassFigure 2 - Resin Mix

MESH STRUCTURES

STANDARD PANEL SIZES

MESH STRUCTURES: THICKNESS (mm) х Mesh Size (mm х mm)

THICKNESS: 26 mm

Mesh: 38mm x 38mm

Side А: Inside Mesh Size 32x32mm, Rib width 6 mm

Side В: Inside Mesh Size 33x33mm, Rib width 5 mm

THICKNESS: 30 mm

Mesh: 38mm x 38mm

Side А: Inside Mesh Size 32x32mm, Rib width 7 mm

Side В: Inside Mesh Size 33x33mm, Rib width 5 mm

THICKNESS: 38 mm

Mesh: 38mm x 38mm

Side А: Inside Mesh Size 32x32mm, Rib width 7 mm

Side В: Inside Mesh Size 33x33mm, Rib width 5 mm

THICKNESS: 50 mm

Mesh: 50mm x 50mm

Side А: Inside Mesh Size 43x43mm, Rib width 8mm

Side В: Inside Mesh Size 45x45mm, Rib width 6mm

THICKNESS: 30 mm

Mesh: 19mm x 19mm

Side А: Inside Mesh Size 13x13mm, Rib width 5-бmm

Side В: Inside Mesh Size 33x33mm, Rib width 5mm

THICKNESS: 38 mm

Mesh: 19mm x 19mm

Side А: Inside Mesh Size 13x13mm, Rib width 5-бmm

Side В: Inside Mesh Size 33x33mm, Rib width 5mm

Mini-mesh Grating (19x19) has a 12mm x 12mm open mesh area. The smaller opening prevents objects as small as 13mm from falling through and complies with the European 15mm ball failing test requirement. The smaller holes also offer smooth movement for small wheeled trolleys, wheelchairs etc.

SURFACE TYPES

1. Concave Surface - original type of grating surface which has curves inwards during the thermosetting process.

Mesh size: 19x19 mm

Mesh size: 38x38 mm

Mesh size: 50x50 mm

The concave edges received at by this process ensure good anti slip properties.The concave surface can be applied to any GRP grating mesh or panel size, for any resin system.Concave grating is more suited to low foot traffic areas and is particularly suitable for hygiene applications where a high standard of slip resistance is needed and ease of cleaning is a consideration.

CONCAVE - Weight, kg/sqm

Base - MESH SIZE X HEIGHT mm

38x38x26

38x38x30

38x38x38

19x19x30

19x19x38

50x50x50

38x38x26

38x38x30

38x38x38

19x19x30

19x19x38

50x50x50

WEIGHT - kg/sqm

12,5

15

19

19

21,9

22

2. GRITTED / Sanded Surface

Gritted surface is applied to the concave surface together with a resin.

Grit Type

Silica sands containing> 98% SiO2.Silica sand from European supplier is manufactured according to ISO 9000 and ISO 14000.

Standard grit size

1.Small (default): Standard grit size: 0,6 - 1,2 mm

2.Medium: Standard grit size: 1,0 - 1,8 mm3.Mixed: Standard grit size: 0,6 - 1,8 mm

Type of resinGritted gratings in top are painted with vinylester mix

Additional thickness1 - 2 mm

Additional thickness

1 - 2 mm

Additional weight0,2 kg/m2

Examples of GRP Gratings with GRITTED / Sanded Surface

GRP Gratings + GRIT (open mesh)

GRP Gratings Solid type panel (covered)

3. Solid Panels

Solid panels (covered top) is typically 1,5 mm thick and is bonded to the grating panel after manufacture. This creates a strong but lightweight covered panel. All panels are available with either gritted or smooth surface. Ideally suited to service trenches, access pits, gully covers, walkways and cable troughs etc. All types and sizes of gratings are available with covered tops.

Examples of GRP Gratings - Solid Panels

GRP Gratings - Solid Panels

4. Sandvich Panels

Sandwich panels (both sides covered) is typically 3mm thick and is bonded to the grating panel after manufacture. This creates a strong but lightweight covered panel. All panels are available with either gritted or smooth surface.

5. CONDUCTIVE gritted / sanded surface

GRP Gratings (GRP Plates) with Conductive Surface is formulated with a carbon black surface, eliminating hazardous static electricity when properly grounded.Available in all resin finishes, NOWENTA Gratings are primarily used in the high-tech electronic industries, munitions and arsenal manufacturing plants and other spark sensitive environments where sophisticated equipment may be damaged due to static electricity.Conductive gritted GRP Gratings have been developed to drain off the build-up of dangerous static electricity in applications where static electricity present safety concerns.The conductive gritted surface can be applied to any GRP molded grating, incl. HLU, mesh or panel size, to an resin system.

Top layer

Vinyl Ester mix with 20% Graphite

Color top layer

Black

Electric strength

< 60 * 103 Ω /m

Examples of GRP Gratings with Conductive Surface

CUTTING & INSTALLATION

Gratings can be cut or molded to our client is specifications. The cut edges are sanded and sealed with resin to ensure corrosion resistance.1. Tolerance per full panel: +/- 3mm in length and width direction, +/- 1,5mm in thickness direction Warp tolerance: Length: 4,5mm per meter, Width: 2,5mm2. Tolerance for cutting: Length: +/- 5mm, Width: +/- 5mm, Circle: +/- 2mm

Ways of obtaining the necessary dimensions:

Standard panel sizes

Blocking Molds

Mold can be blocked along the length direction and width direction. This option is beneficial only if Extra Cost for Blocking is less than Extra Cost for Standard cutting.

Mold can be blocked along the length direction and width direction. This option is beneficial only if Extra Cost for Blocking is less than Extra Cost for Standard cutting.

Standard Cutting

Extra Cutting

Cutouts from grating